Casino name Casino name |

Vulkan Vegas |

Official site Official site |

www.vulkanvegas.com |

Services Services |

Mobile/browser version |

Owner Owner |

Vulkan Ltd. |

Licence Licence |

Yes, issued by Curacao |

Foundation date Foundation date |

2016 |

Language Language |

Multilingual |

Contact phone Contact phone |

[email protected] |

e-post e-post |

[email protected] |

Support Support |

Yes, 24/7 |

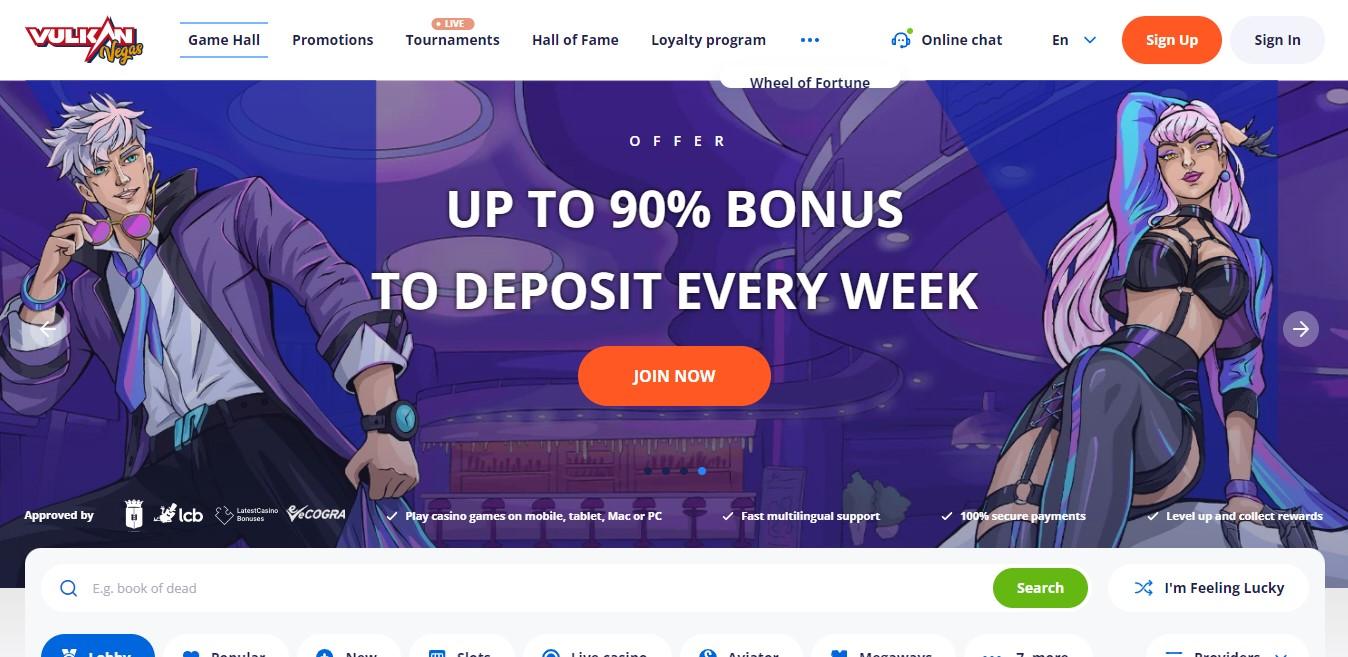

Vulkan Vegas Casino Bonus

Many platforms offer regular and new players profitable and not very bonus programs. With their help, you can get discounts, additional free spins and participate in other loyalty systems. Vegas Vulkan also did not bypass the development of bonus programs for its customers. What casino bonuses can be used by new players and regular users? Let’s figure it out.

Bonus “Welcome”

The program is designed for new players, including first, second and third deposits. Players receive a bonus after passing all stages of registration and profile verification. The “Welcome” program includes three stages:

- “Welcome” – the first level. The first deposit is credited with a 100% bonus and 25 free spins. Wager for wagering with free spins is x40. Bonuses are supported on the Book of Dead slot machine. A promotional code for this level of the loyalty system has not been developed, as it is provided automatically to all new customers.

- “Welcome” – the second level. The second deposit is credited with a 125% bonus and 50 free spins. Wager for wagering with free spins is x40. The program applies to the Fortune Dogs slot machine.

- “Welcome” – the third level. The third deposit is credited with a 200% bonus and 100 free spins. Wager for wagering with free spins is x40. Slot machine – Fire Joker.

The minimum and maximum deposit is set by the country supporting the platform. To activate the promotional code, you need to go to the official website of the casino, go to your profile and enter the copied code in a special line. The action of the promo code may be limited, so you should check the official information on the casino website.

Bonus “Deposit”

The bonus is available to regular players who have already made at least 5 deposits. The amount is determined by the country supporting the platform. The loyalty program applies to the Jungle jJm slot machine with a promo code to activate the slots. You can enter the promotional code in your personal account in a special column. The bonus program gives its participants 20 free spins. You can spend bonuses on the platform specified in the terms of the loyalty system. Usually, the company establishes a list of slot machines to which bonuses do not apply (the list changes regularly, you need to check the exact information on the official website of the casino).

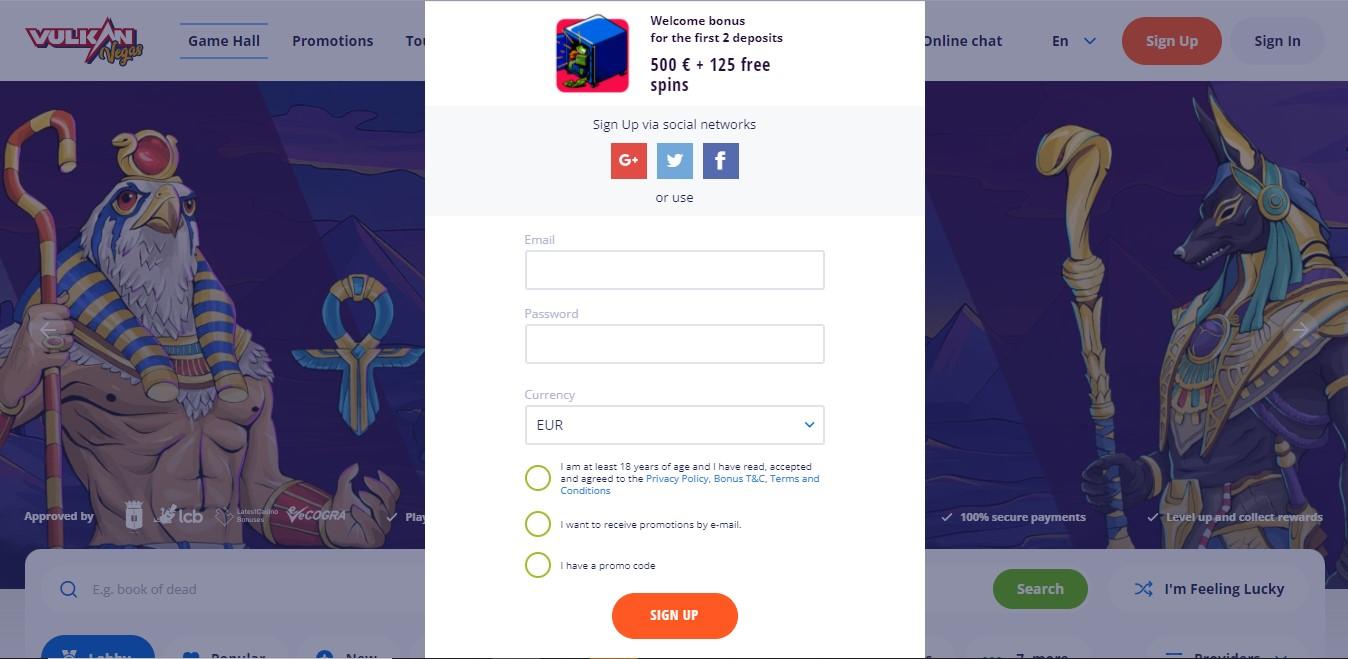

Registration and verification

The casino does not provide players with the opportunity to bypass the registration procedure. There is only a trial version in which you cannot bet money. Therefore, for a normal game, you need to create a profile. The registration process is quite simple. You can register an account on the official website or through a mobile application. Immediately, after registration, a new player gets access to the “Welcome” bonus with a 100% deposit and 25 free spins. For registration you need:

- enter an active email address;

- come up with a strong password (at least 6 characters);

- choose a currency from 18 offered;

- check the age box and agree to the Data Protection Rules, Bonus Terms, Terms and Conditions of the casino;

- Check the box for a promo code.

After that, you need to click on the “Register” button. A profile confirmation email from the company will be sent to the specified email address. To activate your account, you need to follow the link provided in the letter. After confirming the profile in the questionnaire, you must specify the full name, date of birth and personal phone number to complete the account in Vegas Vulkan. To make money transactions, you need to go through the verification procedure and a bank card. Without passing verification, Vegas Vulkan does not provide the ability to deposit and withdraw money and place bets on them, you can only use the issued chips. It is recommended to go through the verification procedure immediately so that in the future there will be no problems with the withdrawal and deposit of money. For this you need:

- Attach a scan of your passport. You can take a picture of the face data page and upload it to the site.

- Attach a bank card in your name.

In this case, you may additionally need to upload your photo of the type that is placed in the passport or another in official style on a light background. The casino administration checks the information about the person for some time, after which it confirms the verification or refuses it if there are any problems with the documents or errors in filling out the data.

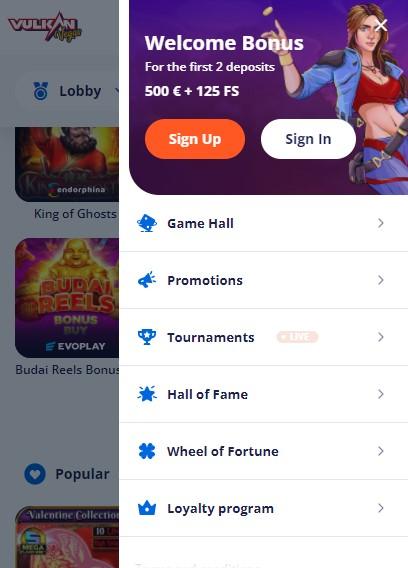

Mobile version and Vegas Vulkan casino app

The presence of a mobile application or a version for the phone is a criterion for the integrity and quality of the company, since only good companies bother with the creation of such a casino format. Vulkan Vegas has both a mobile app and a mobile browser version. The opinion of gamers is clear: the casino application from this company is the best and most convenient for playing in any format. The mobile version works directly in the browser through any gadget, and the application requires downloading. The program can be installed on Android and iOS (currently under development, but will soon be released to users).

You can manage your account immediately after downloading and logging into your profile. All the games hosted in the regular computer version are available in the application, in addition, there are no differences in the graphics, all the details are carefully thought out and worked out. The withdrawal of money is carried out in the same way as in the computer version. The mobile application and mobile version provide sufficient security for transactions and account management. So, SSL encryption technologies are used. In addition, all standard service delivery on the portal and in the application is observed, which is confirmed by a license from Curacao and checks from McAfee and eCogra. A significant drawback is the fact that there is no app for iOS yet. The application is under development, so users can use the casino services only through a browser, which is not always convenient. The administration of Vegas Vulkan assures that the development is in full swing and users will soon see a new application.

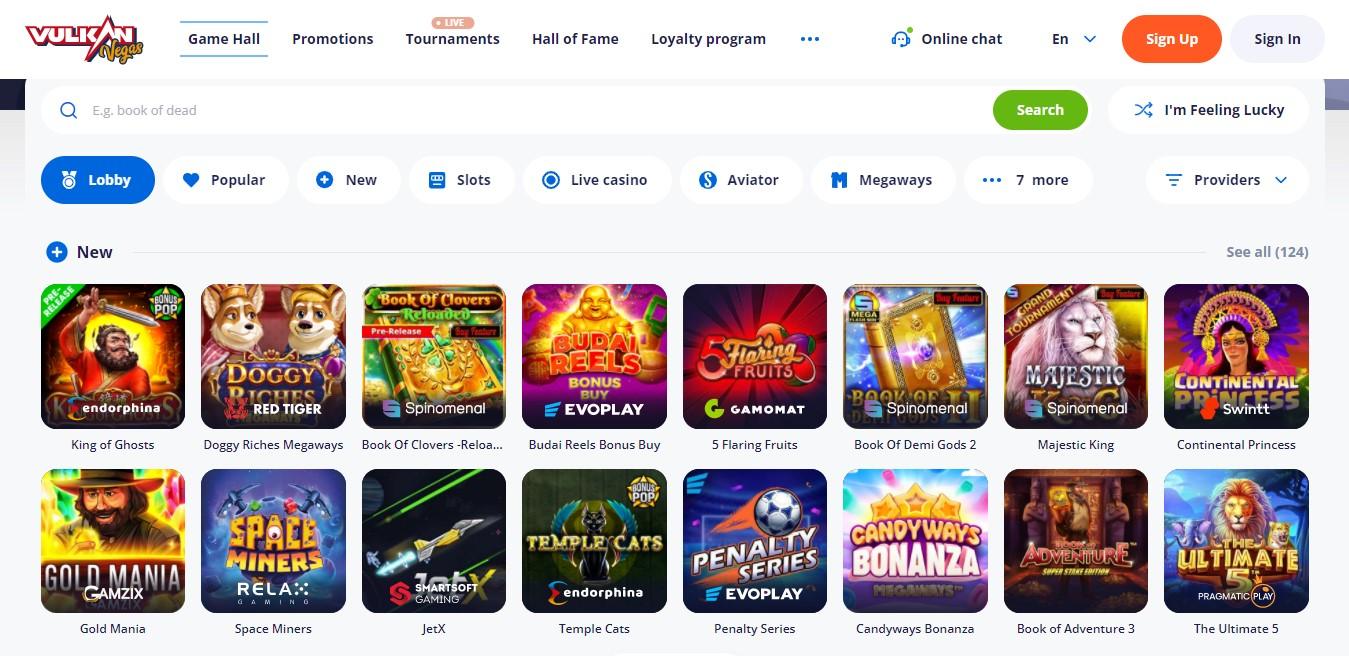

Casino slot machines

Like any casino, Vulkan Vegas has a whole range of slot machines for playing. They are supported on all devices, both in mobile and web versions. The company has its own platform, the approximate number of games is 1600 – this is the largest collection among the casinos. Users get full access to slot machines only after registration and verification, but demo access to the following games is also possible:

- Crazy Monkey;

- Book Of Fruits;

- fruit cocktail;

- Resident;

- money train;

- Redcap.

These machines are suitable for both beginners and professionals. You can play for money in any slots without restrictions. Gamers have analyzed the return: the RTP level is over 90%, and this is a really great result. In addition, the winning system and the rights of the players are protected by the eCOGRA system, which allows Vulkan Vegas to increase the amount of return as much as 99%, so it is really profitable to play at the casino.

Software

The collection of slot machines for the most part is represented by slots with reels, which work on the principle of dropping certain symbols. The reels start in classic or modern mode depending on the game type. In addition, players can play live dealers, lotteries and scratch cards for fast results online. For the convenience of gamers, a convenient software has been developed with a simple search for slot machines. So, on the official website of the casino, users can choose the following categories:

- Lobby.

- Popular.

- New.

- Slots.

- aviator.

- betgames.

- Live casino.

- Card.

- Roulettes.

- Videopokers.

- Quick games.

- Classic slots.

- Other.

- All games.

All software is certified, documents are issued by independent auditors. Each game has a separate random number generator, which does not depend on any circumstances, but only on chance. This makes the process itself as simple, understandable and transparent as possible. Vulkan Vegas works with a large number of software development providers. For example, the company cooperates with EvoPlay Entertainment, Microgaming, Amatic and 40 other organizations.

Live casino

The coolest direction in slot machines is live casino. Live casino is a gambling site in which one of the parties is a real live dealer. In this mode, many games are played, for example, poker. Vulkan Vegas has not bypassed this direction of software, presenting gamers with more than 40 live casinos of various content and orientation. The development of the live casino was entrusted by the providers Betgames, Ezugi, Swintt, TVBET.

Advantages and disadvantages of the casino

The casino market is represented by many companies that implement gambling activities. Vulkan Vegas is one of the leading, located in Cyprus in the city of Limassol. What is it connected with? Let’s analyze the advantages and disadvantages of the casino and decide whether it is worth playing on the slots of this platform or better to choose something else. Advantages disadvantages

- the platform supports 8 languages;

- more than 10 different payment systems are supported;

- the platform is available worldwide;

- huge software – more than 1600 games of various profiles;

- high speed of processing requests and withdrawing funds within 24 hours;

- no transaction restrictions;

- there is a mobile application with economical traffic, simple navigation, light weight and convenient download;

- the platform works absolutely legally;

- support service works around the clock;

- data security and confidentiality is a priority for the administration. – gamers do not rate the game highly: only 3.1 out of 5 stars;

- many gamers are faced with the dishonesty of the platform (although they may just have encountered scam mirror sites).

According to its characteristics, Vegas Vulkan is a fairly reliable and proven casino with slot machines. The main thing when choosing a site is to carefully check the availability of a license, its number, and only after that proceed with registration. Do not trust your data to the first site you come across, as you can easily stumble upon scammers who want to cash in on your inattention.

Banking, methods of input and output

The casino supports the following payment systems (deposit and withdrawal): VISA, MASTERCARD, MAESTRO, SKRILL, NETTELER, PAYSAFECARD, WEBMONEY, CRYPT, PAYPAL, PAYEER, PIASTRIX, ECOPAYZ. There are no transaction limits, so players can deposit and withdraw any amount. To deposit and withdraw funds, the user must leave an application, provided that the profile is completely filled out and confirmed. The time for crediting funds is 24 hours, but on average it is no more than 2 hours. An important feature of the casino is that you can only transfer money to your profile account from your own payment system. It is prohibited to use cards, e-wallets or other means of third parties. Such operations will not be carried out, and the administration may take measures to limit the possibilities of players. Cash is not accepted by the system, only wire transfers.

Support

For the convenience of Vegas Vulkan players, a round-the-clock support service has been developed. You can contact the hotline using a convenient online chat in Russian and English. To get help, just find the “Help” button and click on it, after which the user will automatically be transferred to a chat with a support service employee. You can also contact the administration by phone or email. These data are indicated on the official website of the platform in your country. The response of the administration to applications is almost instantaneous, this allows players to quickly get help on all issues. Before contacting the help line, we recommend that you study the FAQ with all the answers to user questions.

Which languages

The Vegas Vulkan platform supports 8 languages, which makes it easy for people from all over the world to use the portal. So, you can choose the following languages in the program: Russian, English, German, Spanish, Portuguese, Polish, Finnish, Chinese. You can set it in the settings when downloading the application or on the site itself at the top or bottom of the page. It is not recommended to use an automatic translator, as this does not provide a quality translation and may lead to serious errors.

What currencies

The developers of Vegas Vulkan did their best. Players can choose almost any currency for easy transfers from anywhere in the world. Thus, the platform supports deposits and withdrawals in the following currencies: RUB (ruble), USD (dollar), EUR (euro), CAD (Canadian dollar), PLN (Polish zloty). You can choose the currency in the mobile application or on the website when making money transfers.

License

Vegas Vulkan paid special attention to obtaining certificates for the implementation of qualified services. The gambling activity itself is carried out on the basis of the Curacao license with the number 8048/JAZ2012-009. The company itself is registered in Cyprus. The license confirms the quality and safety of the services provided and compliance with international standards in this area.

promo codes

- options try

- blackjack $

- video sign

- experiencing €

- baccarat promotions

- look us

- cashback know

- vulkanvegas matched

- points closed

- rewards netent

- vip based

- keno betsoft

- run variety

- hold safe

- neteller yggdrasil

- policy earn

- lucky team

- choice add

- quickspin extra

- reserved section

- weeks wild

- enjoy reload

- studios wheel

- status brivio

- ended updated

- evolution login

- business deal

- single news

- today home

Recently I decided to register on the official page of Vulkan Vegas, received free spins and even wagered them, and then put them on withdrawal. But, this is where things get interesting. The administration asked to verify the account, I submitted the documents and have been waiting for an answer for the whole day. Technical support gives general answers and asks to wait a bit. The site itself is not bad, but the withdrawal and verification procedure is very long.

Good afternoon! In order for you to withdraw funds from the platform, the site administration must make sure that you are a real player. Usually, on the Vulkan Vegas website, customer identification is carried out within 1-3 days, and after that you can apply for a withdrawal of money.

I have been playing at the Vulkan casino for quite a long time. At first, I had to get used to this kind of gambling entertainment for a long time, but gradually I got involved in the process. But, the site says that the minimum possible withdrawal is 500 Dollars, and as soon as I started withdrawing, then immediately 3,000 Dollars !!!

Hello! There are several withdrawal / deposit methods on the site, each of which has its own specific limits. So, for example, you can withdraw 500 Dollars to the e-wallets presented here. While the minimum possible withdrawal for bank cards is 3,000 Dollars.

What I want to explain is that there is no one working on my account and taking half of the profit